The solutions developed within the project’s spec will be deployed in

1 demonstrator, ensuring the integration, commissioning, and set-up of the open innovation platform.

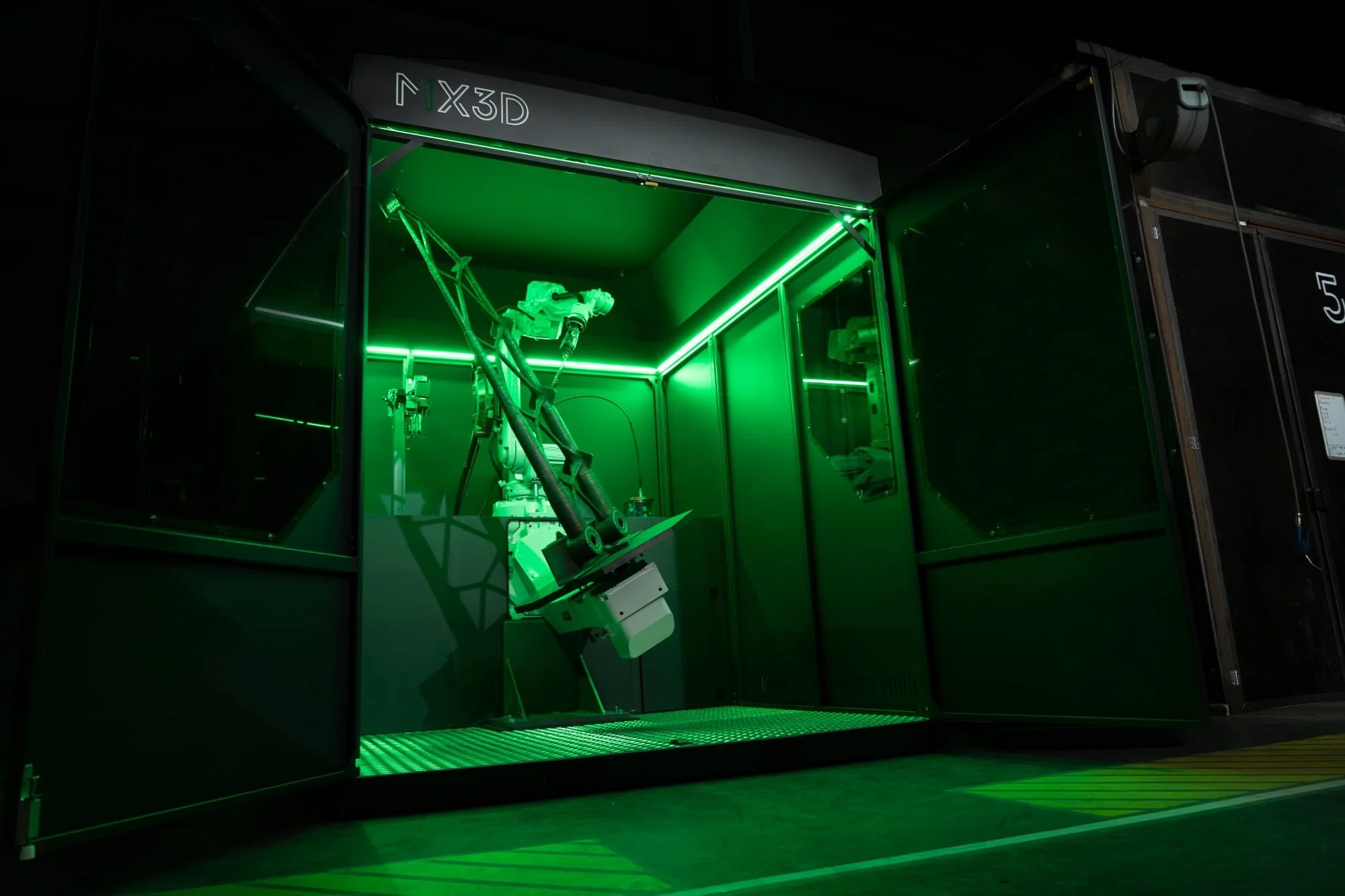

Metal Additive Manufacturing for Construction

PILOT 1

Metal Additive Manufacturing for Construction

In a typical steel-framed building, much of the material is often underutilised and at a high economic and environmental cost.

This use case aims to increase structures’ efficiency through hybrid construction, combining traditional rolled steelwork with a small amount of additively manufactured material. The proposed hybrid construction concept can be used for beams and frames,

where metal additive manufacturing can improve structural efficiency by adding material only where needed on a conventional I-section profile. This results in a 35% increase in load-carrying capacity with only a 10% increase in material use. Similarly, when it comes to trusses optimisation, WAAM (Wire Arc Additive Manufacturing) can create trusses with more complex shapes while still using conventional materials, saving time and lowering costs.

▪ Fast-running topology optimisation techniques to generate efficient joint geometries.

▪ Design of an optimised and certified metal component, utilising data interoperability, thermomechanical models, and manufacturing planning strategies.

▪ Adaptations to the WAAM process pipeline.

▪ Hybrid construction solution by combining AM (Additive Manufacturing) with traditional rolled steelwork and taking advantage of AM to build local features that increase load-carrying capacity.

▪ Real-time re-optimisation to tackle thermal distortions during the printing process.

Induction Welding for the Assembly of Thermoplastics in Aeronautics

The welded assembly process was initially developed for carbon fabric-based laminates. However, the aeronautical industry is currently focusing on replacing them with UD tape-based laminates, which allow for a high degree of automated production of parts by using advanced, fully automated tape placement processes. The challenge is that the UD tape results in a fibre architecture that is more sensitive to small material and/or process-induced variations when it comes to induction welding.

This is where PIONEER comes in with the aim of creating a digital model of the induction welding process, developing synthetic datasets which quantitively link process parameters to weld performance indicators. By accurately controlling the process and monitoring the weld quality during the process, the need for post-weld inspections is greatly reduced.

PILOT 2

▪ Set up an accurate induction welding simulation model.

▪ Set up a model that will act as a digital twin to consider inline data and data from simulations.

▪ Set up an inline process control system.

▪ Evaluate parameters and establish correlation by utilising temperature monitoring and measurements from existing sensors.